Pneumatic Conveying System

●Function:

Positive pressure chamber pump dense phase conveying system

AL positive pressure dilute phase pneumatic conveying system

Negative pressure vacuum pneumatic conveying system

Nitrogen closed-loop delivery system

NEXT:Dosing and batching system

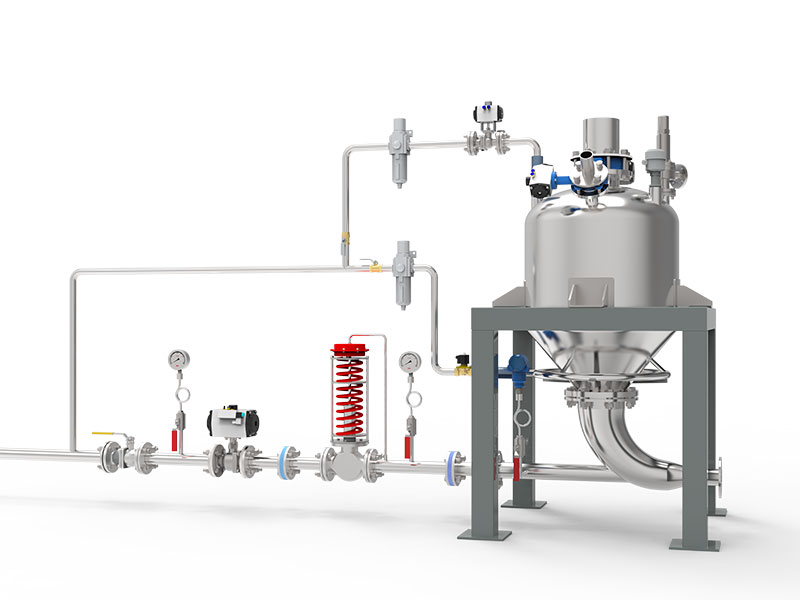

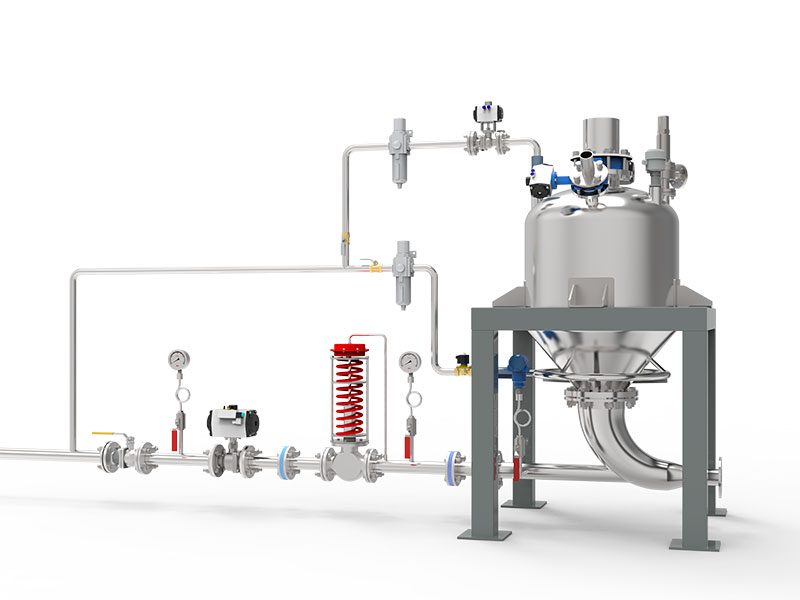

Positive pressure dense phase conveying system

It has the characteristics of large conveying capacity, long conveying distance, low conveying speed, and high material to gas ratio, and is suitable for easily broken materials or high abrasion materials.

Positive Pressure Dense Phase Conveying System |

Conveying Pressure: 150-400 kpa |

Conveying Distance: <1000 m |

Flow Velocity: 4-12 m/s |

Feature: |

High mixing ratio, low energy consumption, reduced pipe diameter, minimal filamentation and product degradation, and low pipeline wear. Requires compressed air station support and entails higher initial capital investment. |

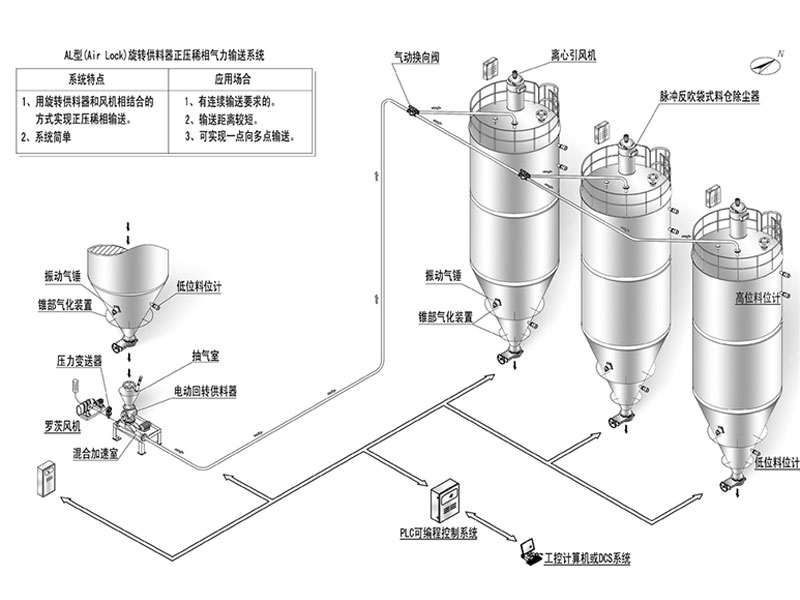

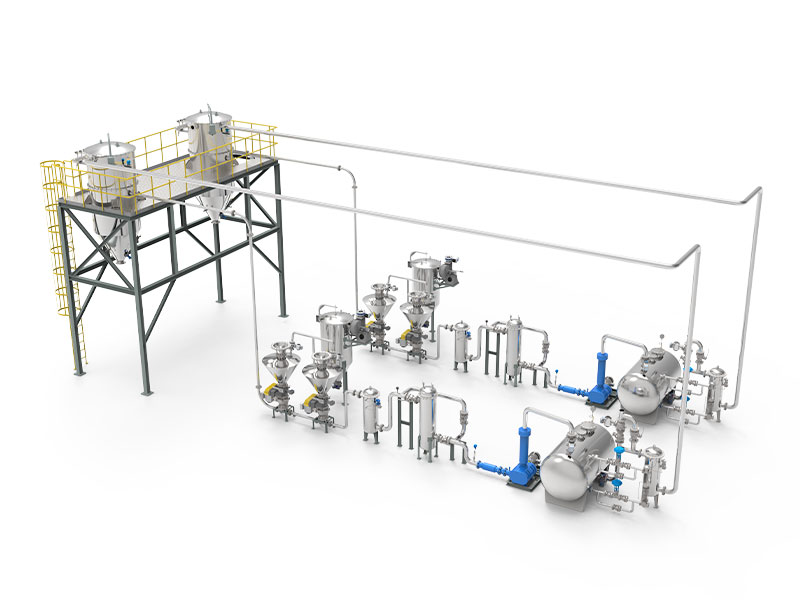

Positive pressure dilute conveying system

Positive pressure dilute conveying system: dilute phase conveying: solid content less than 1-10kg/m3, high operating gas velocity (about 18-30m/s), conveying distance basically within 300m. Generally, Roots blower is used as the power source, and powder materials are unloaded into pipelines for pressure feeding through rotary valves or screw feeders. The conveying pipelines can be flexibly arranged to achieve one point to multiple points of conveying, thus making the factory equipment process configuration reasonable; The system is airtight, with little dust flying out and good environmental hygiene conditions. There are few moving parts, which is convenient for maintenance and easy to realize automation.

Positive Pressure Dilute Phase Conveying System |

Conveying Pressure: 20-80 kpa |

Conveying Distance:<200 m |

Flow Velocity: 16-30 m/s |

Feature: |

Single-point to multi-point material transfer with simple system architecture, reliable operational stability, lower capital investment, and low mixing ratio. Suitable for most industrial applications requiring flexible material distribution. |

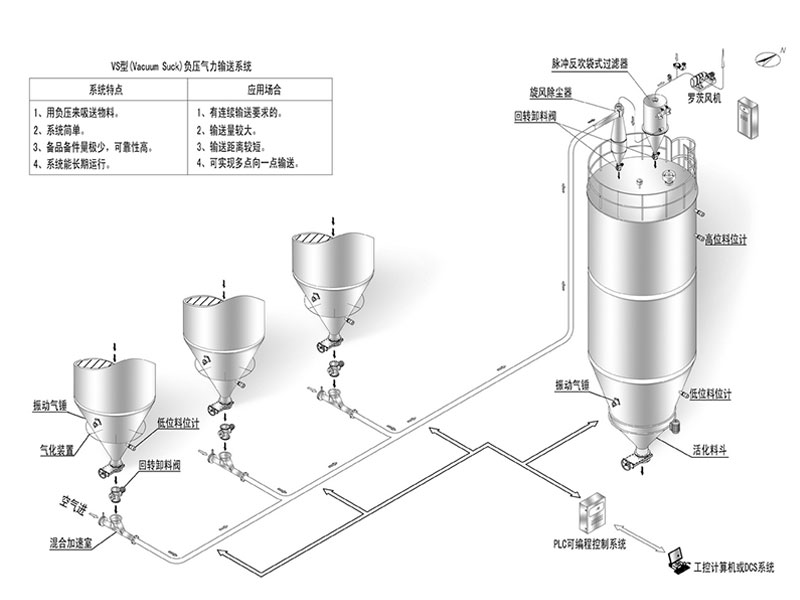

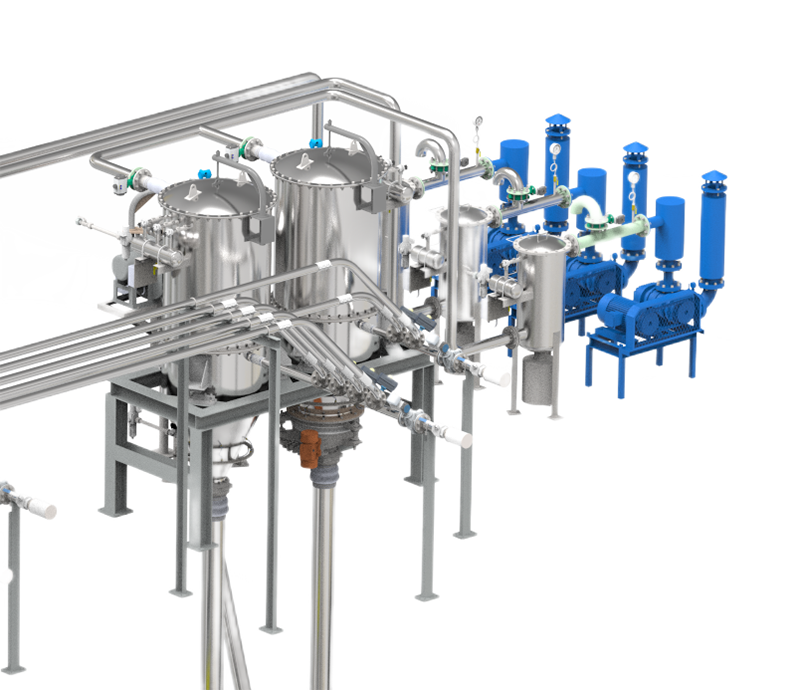

Vacuum conveying system

Negative pressure conveying system: The advantage of negative pressure dilute phase pneumatic conveying is that it is easy to retrieve materials and suitable for situations where no dust is required for material retrieval; Suitable for situations where material is taken from low, deep, narrow sampling points, or when feeding is concentrated from several locations to one location; Due to the gas source being located at the end of the system, lubricating oil or moisture will not mix into the transported material; Due to the pressure inside the conveying pipe system being lower than atmospheric pressure, even if there is wear and gaps, the conveyed material will not leak; Due to the pressure inside the conveying system being lower than atmospheric pressure, moisture is prone to evaporate, making it easier to transport materials with high moisture content compared to pressure conveying.

characteristic:

1. Suitable for centralized transportation from multiple locations to one location. The feeding point can be one or several, and the feeding pipe can be equipped with one or more branch pipes. Not only can materials from multiple feeding points be transported to the unloading point in sequence, but materials from multiple feeding points can also be transported to the unloading point simultaneously.

2. Under negative pressure, the material is easily sucked in, so the feeding at the throat is simple. The hopper can be opened for continuous feeding and conveying.

3. Materials are transported under negative pressure, and moisture is easily evaporated. Therefore, for materials with high moisture content, they are easier to transport than pressure feeding; The material supplied in a heated state can be cooled by transportation.

4. The components need to be sealed, and the construction of components such as national separators, dust collectors, and air locks is relatively complex.

5. The fan is located at the end of the system and requires a high degree of air purification.

Vacuum Conveying System |

Conveying Pressure: -90 kpa to -10 kpa |

Conveying Distance:<100 m |

Flow Velocity: 6-30 m/s |

Feature: |

Multi-point to single-point material transfer, dust-free pipeline operation, optimal for short-distance applications. Energy consumption increases exponentially with extended distances. Ideal for handling toxic, explosive, or hygroscopic materials requiring closed-loop containment. |

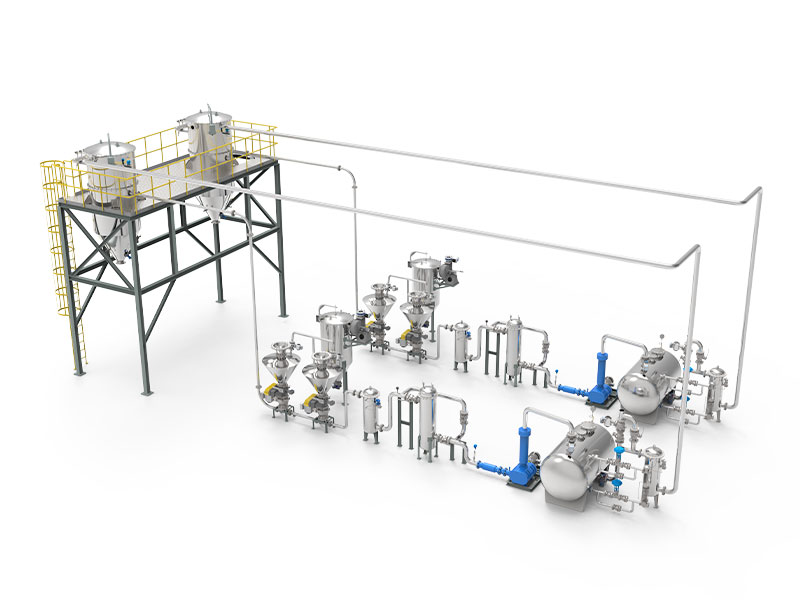

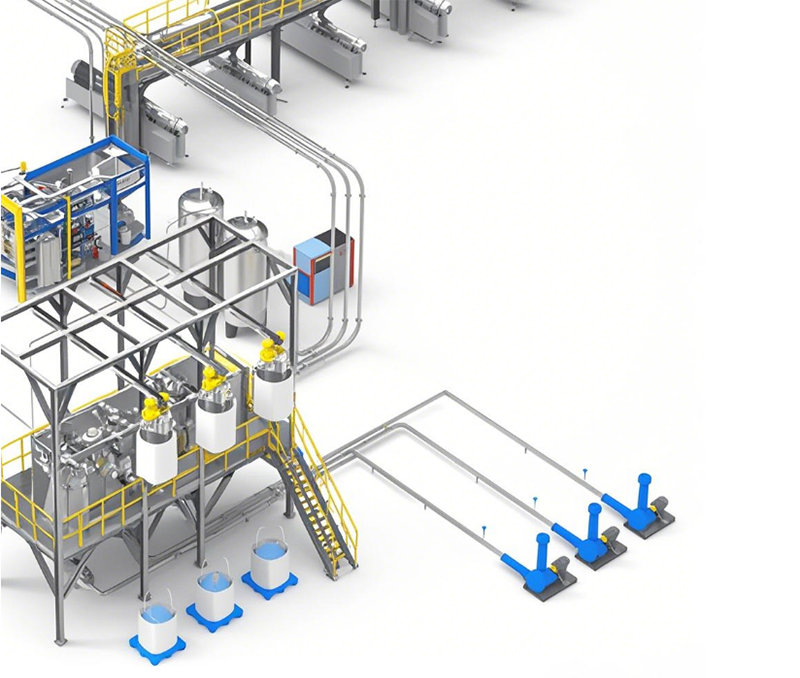

Nitrogen closed-loop conveying system

For materials that are prone to moisture absorption, oxidation, and have a risk of explosion, a nitrogen closed-loop pneumatic conveying method is adopted. The system is in a nitrogen sealed environment, and the system automatically adjusts and operates according to PID. Nitrogen is circulated for stable and reliable transportation, greatly reducing energy consumption and operating costs.

Nitrogen Closed-Loop Conveying System |

Operating Pressure: 30-80 kpa |

Conveying Distance:<200 m |

Flow Velocity: 16-30 m/s |

Feature: |

Specifically designed for hazardous materials (explosive/toxic), hygroscopic or deliquescent substances. Features protective gas recirculation with closed-loop nitrogen recovery and purification. Demonstrates high cost-effectiveness in oxygen-sensitive processes requiring inert atmosphere protection. |

Efficient and intelligent material handling

Innovation brings the future.

An optimal material handling system can not only bring great profit margins to customers, increase production, improve efficiency, reduce labor, material, and material consumption costs, but also provide excellent working environment, visiting environment, and industry status for factories, ultimately steadily moving towards a complete intelligent and modern factory

Our vision is to become a global leader in intelligent solid material handling and promote sustainable industrial development through technological innovation

CZL - enables every material to accurately reach the future!

русский

русский Deutsch

Deutsch Français

Français